Process development and process optimization are among our core competencies. The process, the procedure is in the focus and must be regarded as the most important criterion for the design of the suitable inductive heating system.

If you have your optimized inductive process under control while taking costs into account, you can also produce economically. We would like to help you to benefit from this know-how which has grown over decades.

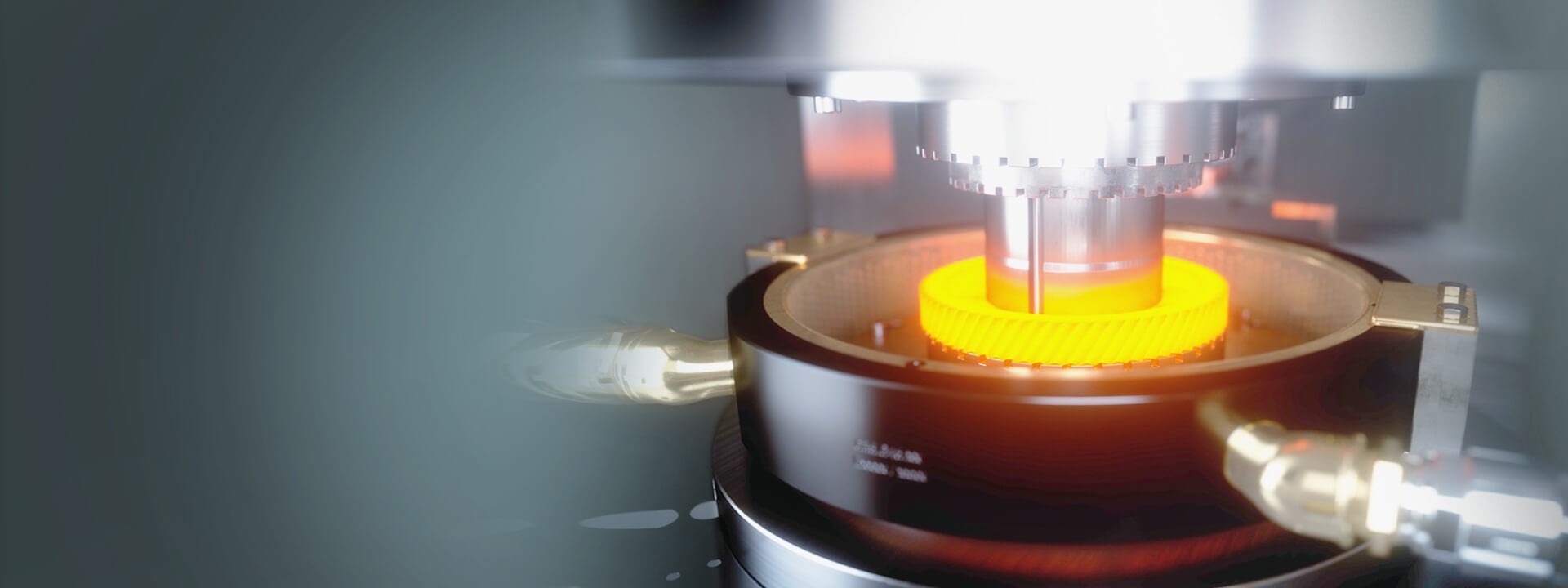

A highly qualified and motivated team as well as various hardening systems with different performance data are available in the specially designed test and development department to optimize the processes.

Within the scope of induction heating, we offer srvices for a wide range of induction heating applications. These areas include:

In addition, we are at your side for complex handling and interlinking issues.

We will be pleased to answer your questions and advise you on your specific challenges.